Engine Decarbonization and Its Benefits for Commercial Users

“Decarbonization” is a relatively new concept. In public discourse, this term appeared parallel with the raised public awareness regarding climate change and global heating. Today, it is imperative, especially in the transport and industrial sectors.

Ethical approach at the same time a desirable business model

The good news is that an ethical approach in terms of ecology is at the same time a desirable business model, for which an increasing number of doors and possibilities is opening, whereas, on the other hand, the so-called “dirty” technologies are increasingly restricted by regulations and are facing a “closed door”. It is an irreversible process and we should all be aware of it, especially the leading people in the industry and political structures.

Engines need to be “healthy”, because it saves money

When we are talking about the specialization called “engine decarbonization”, we are in fact talking about the practice of cleaning the entire system with hydrogen which is produced through water electrolysis, from the intake manifold, through the engine interior, to the exhaust system, which we wrote about in more detail before.

The benefits and advantages of engine decarbonization for business entities and companies with big vehicle fleets are great. We are not talking just the sheer ecological aspect here, a cleaner combustion and the consequent reduction in the emission of harmful gases. Another thing in focus is saving, both when it comes to fuel and servicing and replacement of the mostly expensive parts.

Ethical approach at the same time a desirable business model

The good news is that an ethical approach in terms of ecology is at the same time a desirable business model, for which an increasing number of doors and possibilities is opening, whereas, on the other hand, the so-called “dirty” technologies are increasingly restricted by regulations and are facing a “closed door”. It is an irreversible process and we should all be aware of it, especially the leading people in the industry and political structures.

Engines need to be “healthy”, because it saves money

When we are talking about the specialization called “engine decarbonization”, we are in fact talking about the practice of cleaning the entire system with hydrogen which is produced through water electrolysis, from the intake manifold, through the engine interior, to the exhaust system, which we wrote about in more detail before.

The benefits and advantages of engine decarbonization for business entities and companies with big vehicle fleets are great. We are not talking just the sheer ecological aspect here, a cleaner combustion and the consequent reduction in the emission of harmful gases. Another thing in focus is saving, both when it comes to fuel and servicing and replacement of the mostly expensive parts.

Exhaust gas treatment systems

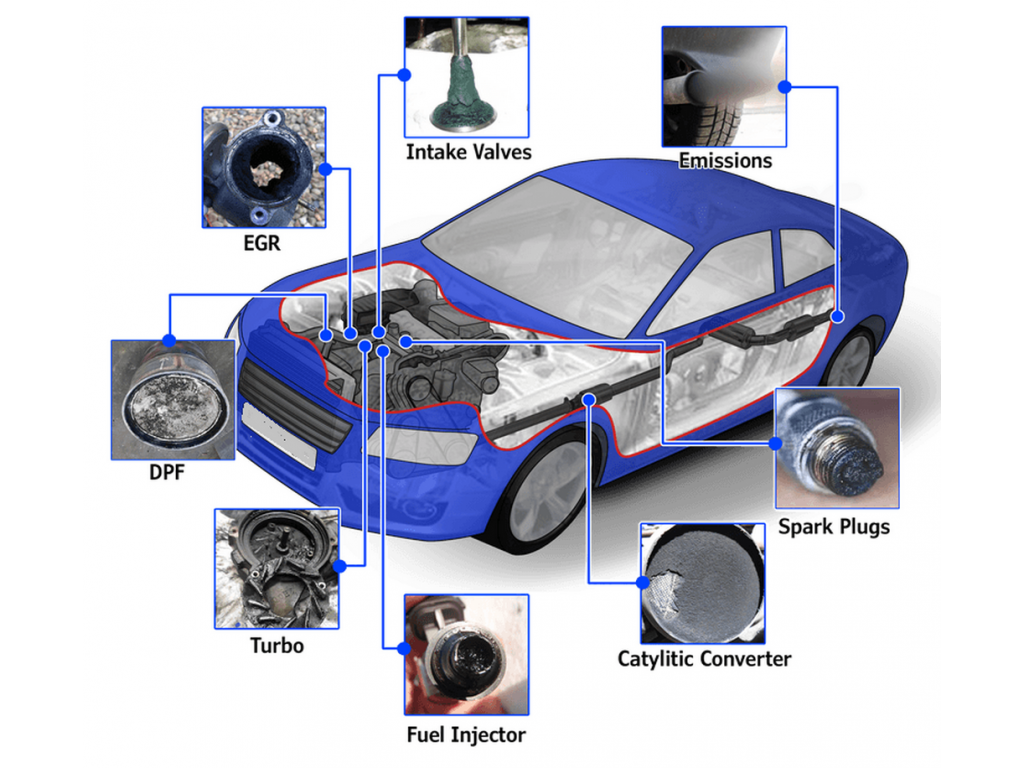

A vehicle that goes through the engine decarbonization treatment is practically brought back to the factory settings regarding its performances when it comes to intake, combustion and exhaust, which is especially important when it comes to vehicles powered by diesel engines, which have a (deserved) reputation as big polluters. As it is well-known, modern diesel engines are equipped with numerous systems for the filtering of exhaust gases, in order to prevent the emission of microparticles and sooth into the atmosphere, which is a serious health hazard.

We will list some of them:

Two-degree and three-degree oxidation catalysts (CAT),

A valve for the recirculation of exhaust gases (EGR/AGR),

Particle filter (DPF/FAP),

A selective catalytic reduction (SCR),

but in addition to said systems, we must mention the other components on which the proper functioning of the system for the treatment of exhaust gases, as well as the performances of the engine, which is also susceptible to sooth particle accumulation and which are sensitive to incomplete or inefficient fuel combustion, depends. Some of them are: the turbine, the MAF sensor, oxygen, temperature and pressure sensors, the intake manifold etc. If any of this is not working properly, in modern systems, it causes a chain reaction and problems in the process, which can even lead to an engine malfunction.

How does one in fact profit from regular engine decarbonization?

Finally, we come to the essence of the problem, especially when it comes to big fleet operators or companies which use a considerable number of vehicles in their operations. Since diesel engines consumer less fuel, in the past decades, it has become a frequent practice to primarily buy them and use them for various activities, including delivery, transport and so on.

However, all said systems entail higher costs as well, especially in the case of intensive exploitation. Catalysts, DPF filters, SCR, all these systems use very valuable or expandable materials. Their replacement is (too) expensive, but it can be adequately solved through regular engine decarbonization, a treatment with the help of which the life cycle of all said systems will be considerably extended and their work more efficient. In addition to being environmentally friendly, you will at the same time have lower costs.

When we compare the price of the decarbonization treatment with the price of the replacement of repair of a certain component from the system of exhaust gas filtering, as well as the savings made on fuel consumption, which everyone can calculate by putting it into the monthly or annual consumption equation minus a minimum of 10%, we come to a clear conclusion as to “what’s better”.

A HEALTHY ENGINE – BETTER PERFORMANCES

Finally, what is extremely important is to get adequate information, to get educated and to choose renowned services with proven, quality machines, otherwise the desired effect will not be there, quite the contrary.

FOTO GALERIJA: